When it comes to optimizing manufacturing plants, every square foot counts. As a growing business, it’s crucial to save space inside your workplace. Whether it’s due to increased demand, or manufacturing a product, every company makes efficiency a top priority.

The first few options which require the least number of changes to plant infrastructure are related to optimizing unused space in the factory. For many, this involves installing a mezzanine or platform to store items like finished products, raw materials, or somewhere new to shift assembly areas.

Another way to maximize existing manufacturing space is to reorganize and consolidate infrastructure by allowing one operator to look after a few pieces of equipment. This can save precious space on the shop floor.

The last two options are the costliest, but may be required in some instances. Building an addition on to the existing plant could be a viable option when extra square footage is needed. Finally, in extreme cases, when plants have outgrown their roots, acquiring a larger facility may ultimately solve those square footage woes.

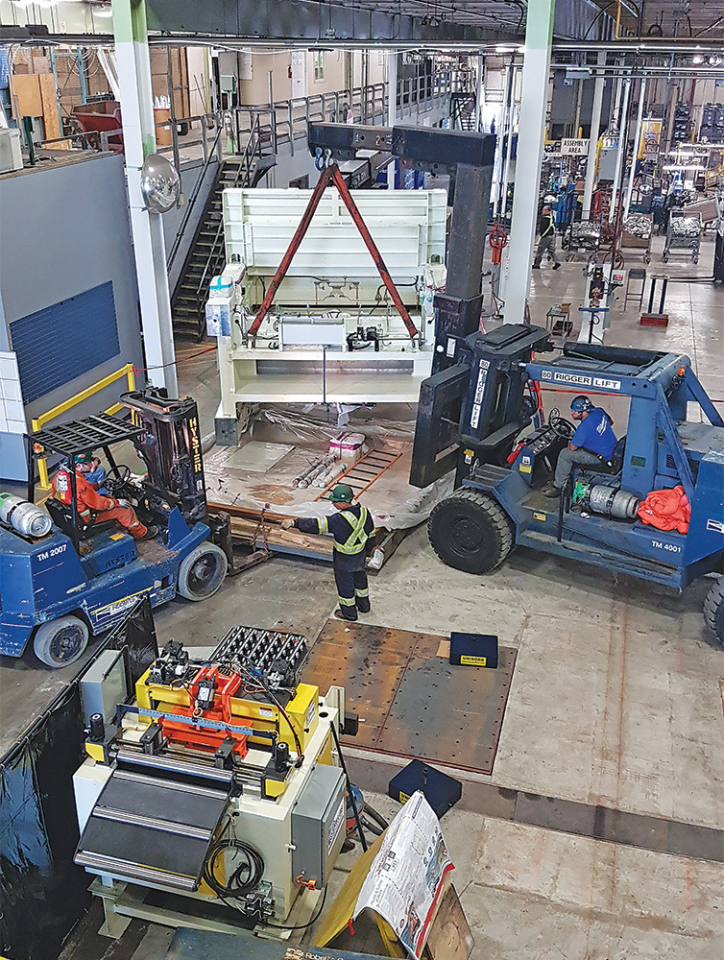

In these situations, minimizing production and revenue loss is key. Roberts Onsite can assist with the careful planning and preparation to help increase efficiency within your facility, no matter how small or large your company may be.

Whether you need assistance with mezzanine construction, plant reorganization, plant additions or building a new factory from the ground up, Roberts Onsite are the experts in plant relocations and machinery moving.