In today's fast-paced industrial landscape, flexibility, efficiency, and speed are paramount. This is especially true when it comes to designing and installing piping systems. Traditional piping systems, with their on-site construction and inherent delays, simply can't keep up. Enter modular piping – a revolutionary approach that offers prefabricated precision for even the most complex construction projects.

What is a Modular Piping System?

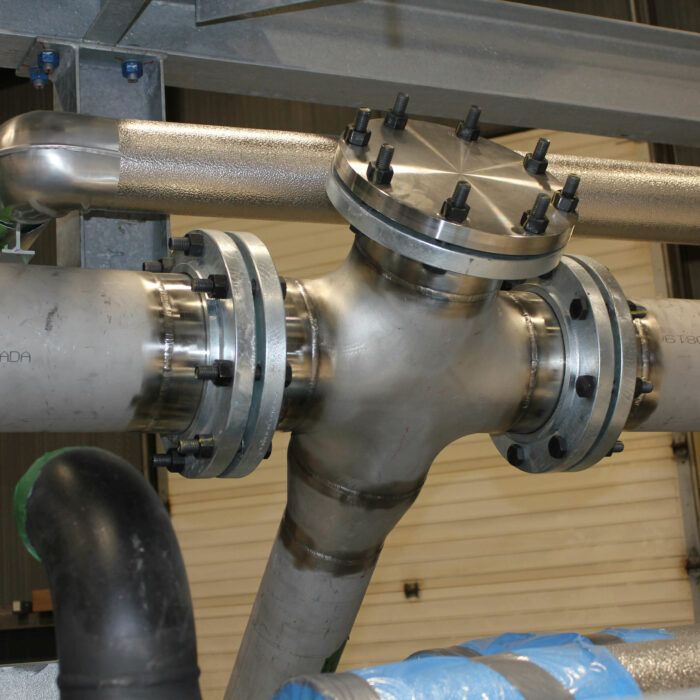

A modular piping system is a pre-fabricated piping solution where pipes, valves, connectors, and other components are designed, manufactured, and assembled in standardized units or modules off-site. These modules are then transported to the installation site, where they can be easily connected to create a fully functional piping system.

Imagine a piping system where pipes, valves, and fittings are meticulously assembled off-site, like a perfectly orchestrated puzzle. That's the essence of modular piping. These pre-built modules arrive at your site ready to be quickly and easily connected, minimizing disruption and downtime.

Key Components of Modular Piping Systems

- Pre-fabricated Pipes: These pipes are cut, bent, and welded in the factory according to precise specifications, ensuring uniformity and high quality.

- Fittings and Valves: These components are also pre-fabricated, offering a range of options for connecting and controlling the flow of fluids within the system.

- Support Frames: A modular piping system often includes support frames or brackets designed for easy installation and alignment.

- Insulation and Coatings: Depending on the application, the pipes may be insulated or coated with materials that prevent corrosion and maintain temperature control.

- Control and Monitoring Systems: Advanced modular piping systems may also include built-in sensors or controls that allow operators to monitor pressure, temperature, and flow rates.

Applications of Modular Piping Systems

The modular nature of this piping system allows it to be highly adaptable, scalable, and suitable for a wide range of applications, including industrial plants, commercial buildings, and residential projects.

- Industrial Manufacturing: In factories and plants where fluid transport is essential, modular systems can help streamline production lines and minimize downtime.

- Oil and Gas: Modular systems can be used in oil refineries, offshore platforms, and pipelines, where rapid installation and easy modifications are critical.

- HVAC Systems: Modular piping systems are ideal for heating, ventilation, and air conditioning (HVAC) systems in commercial and residential buildings, allowing for easier system upgrades and modifications.

- Water Treatment Plants: Modular piping systems are used extensively in water and wastewater treatment plants, where efficiency and scalability are crucial.

- Pharmaceutical and Chemical Industries: In industries where stringent quality and safety standards are required, modular piping systems allow for easy installation and maintenance of sanitary and sterile lines.

Ready to experience the benefits of modular piping? Contact us today to discuss how our mechanical team can bring this innovative solution to your project.