Not long ago, it seemed like electric vehicles were far on the horizon. Due to leaps and bounds in innovation and technology, that time has arrived. Electric vehicles (EVs) are becoming more prevalent on roadways around Canada.

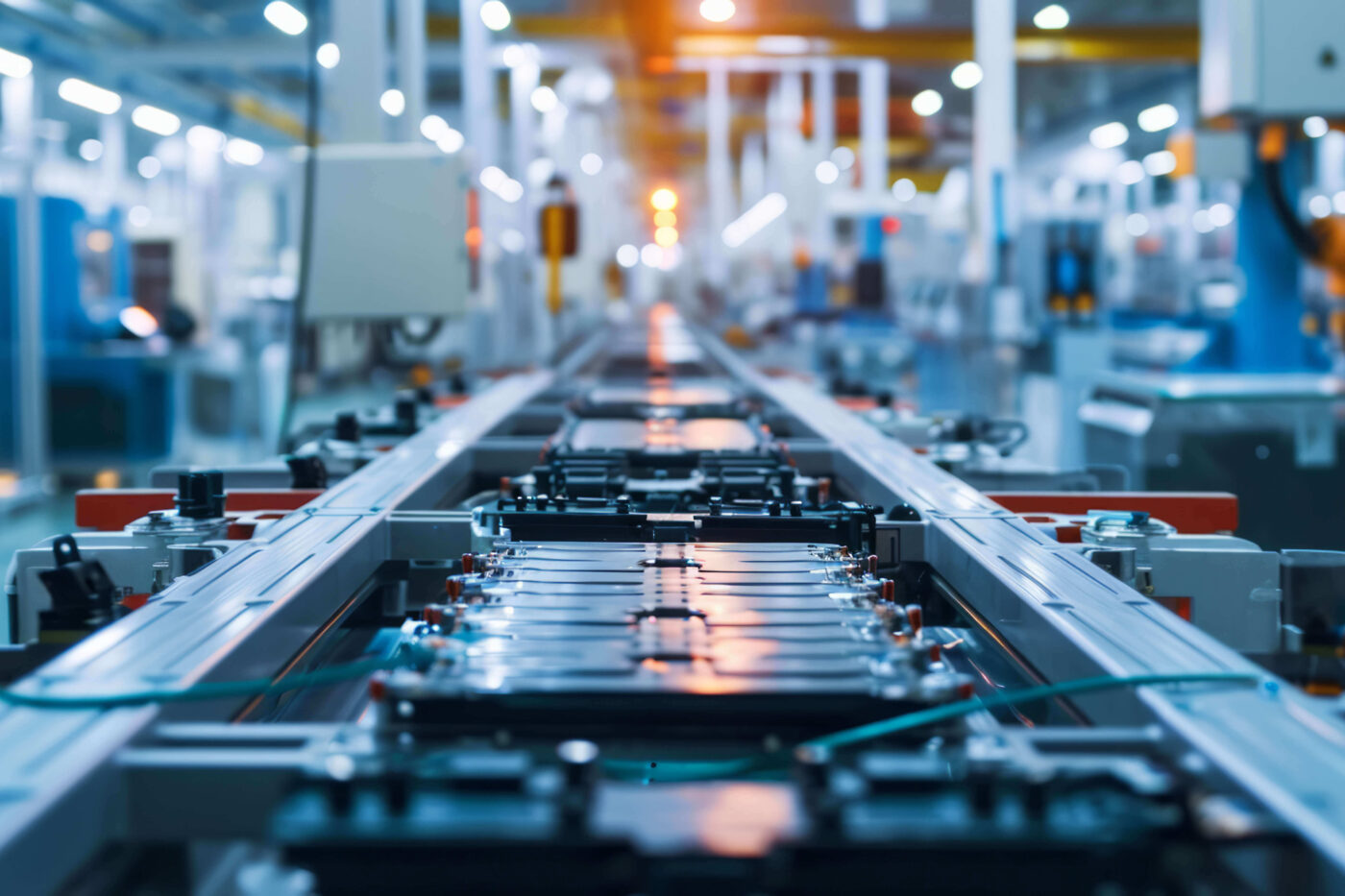

As we approach federal guidelines for electric vehicles, the current government has a target of the year 2035 for 100 percent of all new light-duty vehicles sold in Canada to be electric vehicles. This means many auto manufacturers are retrofitting their assembly lines to accommodate added demand for EVs.

Canada’s first multi-trade contractor for EV battery assembly plants

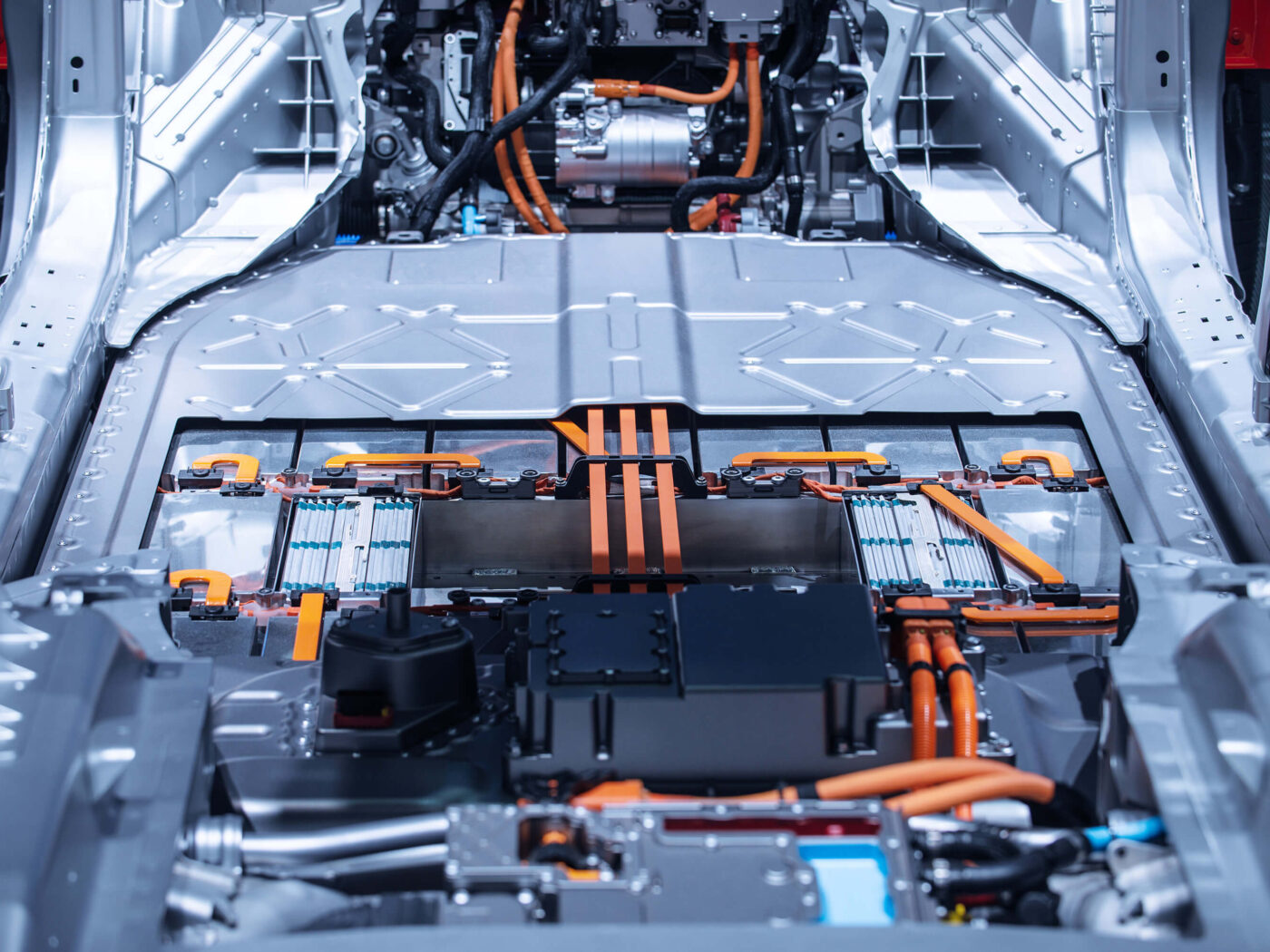

We established our roots as an electrical company and have led many projects in the automotive industry for all the major manufacturers. This time around, the only difference is the facilities focus on building vehicles with high-performance battery packs instead of gas engines.

Some manufacturers opt to start from scratch by gutting their existing space to build an assembly line to accommodate electric vehicle construction. This may include modifying existing conveyors, updating utility services, or installing brand new equipment.

We consult with our clients and try to preserve as much equipment as possible, while also being mindful of the environmental impact of starting with brand new tools and equipment. Retooling part of a plant significantly reduces downtime, ensures a quicker turnaround for the product and is more cost-effective.

In building the EV assembly line, pre-planning is the most critical step

As with any project, pre-planning is the most critical step to ensure a successful result. This starts with three key meetings to establish timelines and expectations for all parties involved.

From a high-level executive meeting, to weekly review meetings, and daily meetings to map out progress three days in advance. This ensures that all contractors synchronize their efforts to achieve maximum efficiency and minimize downtime.

When equipment needs to be relocated, Roberts Onsite will visit the site and make detailed notes on factory testing to observe how the equipment operates. From there, our experts will build a plan for disassembling equipment and tagging items so they can plug and play once they arrive at the new location.

Why choose Roberts Onsite for your EV installation?

Clients have many options for multi-trade contractors, but the difference you get from Roberts Onsite is our knowledge and our people. Our experience in the automotive field is second to none, and with projects in the EV field, we know the ins and outs of making things run smoothly.

Another value-added service we provide is we bring more than just a quote and a blueprint to the table. We often give feedback and ideas on how to maximize efficiency during the new installation. We cooperate closely with other teams in the process to achieve the end targets. This ultimately saves our clients time and money.

If repairs become necessary in the future, our recommendations can make it much easier for your maintenance staff to fix equipment later on.

Due to the pristine nature of EV automotive plants, manufacturing areas are treated much like a pharmaceutical grade environment, which is another area Roberts Onsite also has a wealth of experience.

Our knowledge and our people make all the difference

As the first to market multi-trade contractor in this field, Roberts Onsite can perform an electric vehicle construction or retrofit more efficiently and safely than anyone else. Experience is paramount in this field, and your EV project is always in expert hands when you trust Roberts Onsite.

In some cases, we’ve also completed projects ahead of schedule and under budget. We are flexible with special requests. But more importantly, getting the job done right the first time is priority number one, but these added perks are a bonus in particular projects.

Contact Roberts Onsite today to learn more about our experience in the EV field and to discuss the opportunity to work on your electric vehicle installation or retrofit project.