Being eco-friendly isn't just for homeowners. There are ways businesses and industry can reduce their environmental footprint too.

Heather Burton - April 22, 2021

_______________________________

Even though I am a bona fide adult – with a mortgage payment, and utility bills and everything – I still hear my Mom’s voice in my head as I leave a room. Clear as day I can hear her say: “Heather, I can track your progress around the house by the number of lights you leave on!”

Of course, now that I am the one actually paying the bills, turning the lights off makes a lot more sense than it did, say, when I was 8. But it’s not just about managing one’s expenses is it? It’s also about trying to protect the resources we have, and reducing the impact we have on the environment – one light at a time.

That desire to protect the earth for future generations is strong. We make changes at home, but it doesn’t have to stop there. Business owners and facility managers can make adjustments at the plant that will go a long way to shrinking a company’s environmental footprint. Here are a few ideas that can be implemented at various industrial and commercial work places to help make business operations a little kinder to the earth.

_______________________________

That desire to protect the earth for future generations is strong. We make changes at home, but it doesn’t have to stop there.

_______________________________

Shine a light on it

From office spaces, loading docks, and manufacturing areas, switching to a more efficient lighting system can be a major turning point in helping you reach your corporate environmental objectives.

In terms of energy-efficient lighting technology, LEDs (light-emitting diodes) are where it’s at. The environmental benefits are numerous: they have a longer lifespan – anywhere from 15 to 25 times longer; they consume low amounts of energy; and they emit high levels of brightness without the heat that halogen lights give off. LEDs are known to produce a brighter, higher-quality of light than other lighting options. The lights don’t hum or flicker like some fluorescent lights can, a characteristic that employees who suffer eye strain and workplace headaches will appreciate.

To make the most of the LEDs you can also install motion-activated occupancy sensors to control the lights ensuring that the lights only come on when someone is working in, or has passed through the area.

_______________________________

Once complete over 2,295 fixtures will be replaced and more than 115 occupancy sensors installed to help the customer realize a 67% reduction in energy consumption. _______________________________

Roberts Onsite’s Electrical team is developing an LED lighting upgrade proposal for a long-standing client. Once complete over 2,295 fixtures will be replaced and more than 115 occupancy sensors installed throughout the manufacturing, laboratory and office spaces. This lighting retrofit could help the customer realize a 67% reduction in energy consumption.

This same client truly understands the benefits of LED lighting retrofits. Back in 2019, Roberts Onsite’s electricians replaced 560 fixtures in one part of the plant, an upgrade which helps the client save about 16.8 kW per year.

Take control with an energy management system

The desire to be more energy-conscious isn’t always enough - sometimes we need to know where to look to help us determine areas for improvement.

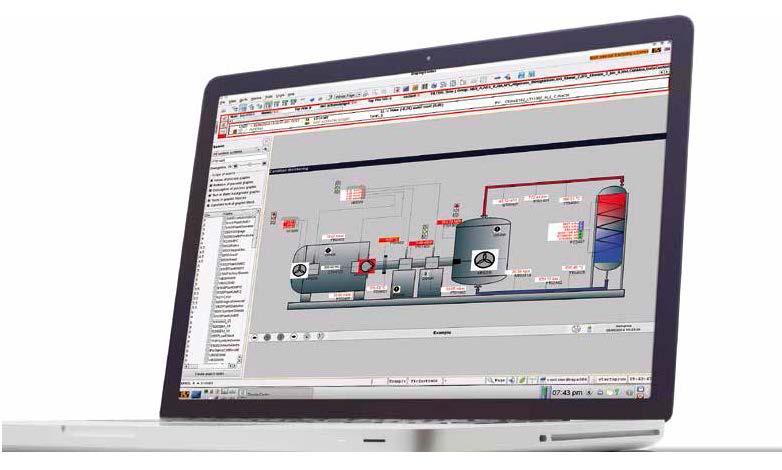

Roberts Onsite’s Automation Controls & Engineering group can help implement a real time energy monitoring and management system and make recommendations based on this data to help cut energy usage and increase efficiencies.

An Energy Monitoring and Targeting System (EMTS) is the basis for long-term sustained improvements. The EMTS records energy usage through various power monitors throughout a facility to determine where, when, and how energy is being consumed. This information is recorded and stored for future reference and baseline comparison.

Based on this information we can help pinpoint process and equipment inefficiencies and recommend a path forward to help improve efficiency and save costs. Energy monitoring does not need to be limited to just electrical power. We can monitor gas, water and compressed air systems at any type of facility to get a full understanding of where the energy is going.

_______________________________

The team can analyze how much energy is spent through the daily running of the facility and use this data to develop achievable energy reduction targets for the company.

_______________________________

Predict where to spend your maintenance budgets

Beyond just energy savings our EMTS can also act as the base of a preventative maintenance system. Preventative maintenance can allow you to reduce overall maintenance costs by understanding exactly when equipment will require maintenance before it breaks down.

The system infrastructure can be expanded to include temperature and vibration sensors on critical infrastructure. Gaining a better understanding into the actual operating conditions of your critical equipment will allow you to get required equipment ordered and in hand in a timely manner to schedule a maintenance window. These systems have also proven to make the practice of scheduled, costly calendar-based maintenance routines obsolete.

Our specialists, adept at infrared thermography, can conduct a thorough scan of the electrical and mechanical equipment in the building. These scans seek out process inefficiencies and act as an early warning system for building systems that may soon fail.

Roberts Onsite’s trained personnel can conduct compressed air audits of your facility using ultrasonic leak detection. This audit can be conducted live during normal production and will help identify air leaks and losses which can over time result in significant wasted energy.

Keep the heat in

In commercial spaces, it can be a challenge to have sufficient fresh air ventilation at a desired temperature without wasting energy. During the colder months, the heating system has to work harder to warm incoming air before it gets circulated throughout the building.

This is when a Heat Recovery Ventilator can help. Roberts Onsite’s Mechanical team can install one of these systems to work with your existing HVAC systems to capture that heat energy of the outgoing stale warm air and transfer it to the cooler incoming fresh air. You’ve already paid to heat the outgoing air – no sense wasting it right?

Heat Recovery Ventilator systems can capture up to 85 per cent of the heat from the outgoing airstream, ultimately ramping up the overall efficiency of the building’s HVAC equipment. In the summer months the heat recovery ventilator pre-cools the incoming warmer air by transferring the heat to the outgoing stale air-conditioned air.

Now's the time

From more efficient lighting technology to letting fresh air in without losing the heat, these are just a few of the ways your business can become more eco-friendly. These fixes may not be instantaneous, but the results will be noticeable.

_______________________________

Heather Burton is a Sales & Marketing Coordinator with Roberts Onsite.