The time had come for a long-time customer to make some extensive repairs to the roof of one of their manufacturing facilities. Several additions to a base building helped to accommodate the company’s growth over the past several decades; however, roof technologies have changed a lot in the past 30 years. This project allowed the owner to upgrade the metal standing seam roof to a seamless rubber membrane cool roof.

To allow the roof top to be repaired, our Electrical team worked with the customer and other trades to remove the rooftop HVAC units. Our electricians disconnected the power, thermostat control and fire alarm tie-ins running to each of the units. The units were then lowered to the ground.

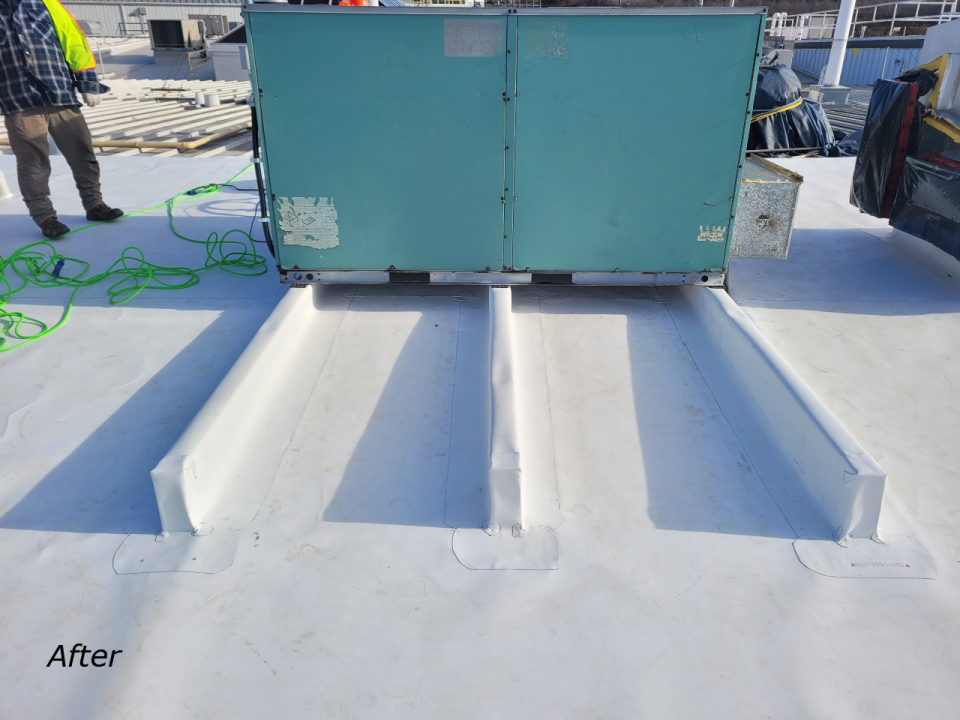

The roofers mobilized to complete the installation of the rubber membrane and equipment support curbs. Several hours later, the rooftop units were raised back into place. Our team then went back to work to make all the electrical connections to get the units up and running.

To minimize the impact on the facility’s operations, the project was completed in several phases over multiple non-production days with two to three units disconnected and reconnected each day.