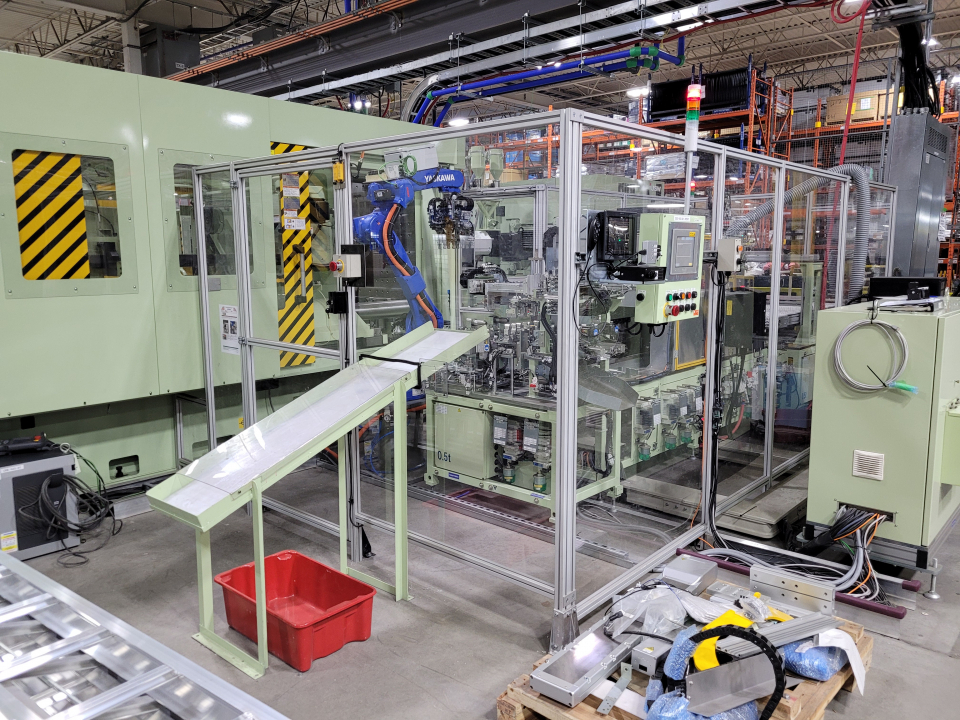

Roberts Onsite was contracted by a local manufacturer to design, fabricate, program, and commission a robotic unload system integration with injection molding machines (IMM) and automation, as part of an overall IMM install. This work was completed for a new production model, as well as improving overall system reliability.

Our automation controls and engineering team designed and built the robot base, aluminum extrusion, clear polycarbonate guarding, and programmed and commissioned the robot unload system.

We supplied and installed the valve bank for the robot end of arm tooling (EOAT), and also installed the robot EOAT.

At Roberts Onsite, we were able to perform all aspects of this job, from trades to engineering, in house.