Roberts Onsite was chosen to be the multi-trade contractor for the oxidizer upgrade project for IKO, a shingle manufacturer in Hawkesbury. This project involves the design and construction of a new oxidizer system facility to provide oxidized asphalt to IKO's existing shingle plant.

The facility is to be built on an area within the plant boundary where an existing IKO asphalt shingle production facility has been operating since 1976.

Roberts Onsite's overall scope of work includes:

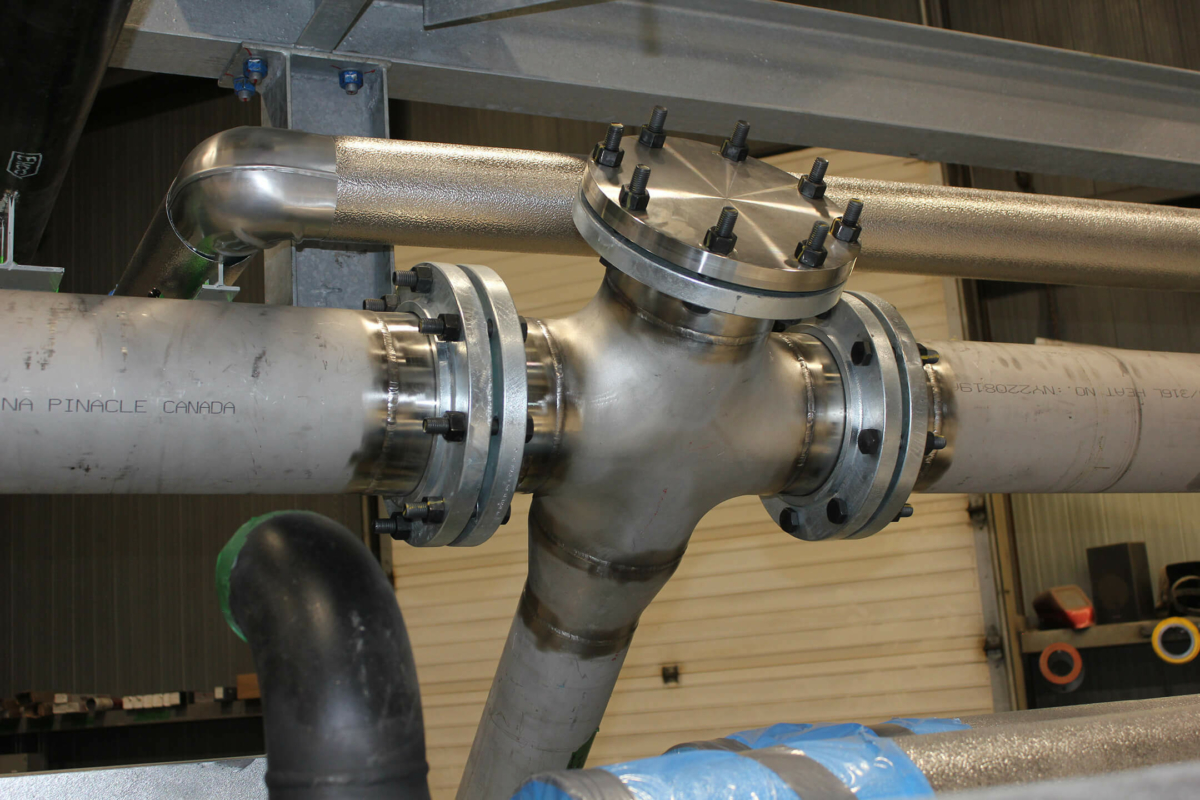

- Fabrication of Pipe Racks will be completed at Roberts Onsite's Fab Shop and shipped fully assembled to IKO's facility.

- Mechanical: Equipment installation

- Piping: Supply, fabricate and install asphalt, hot oil, fume, process oil, process air, ferrous chloride, compressed air, steam, condensate, natural gas, fuel oil and water piping. All required tests must be completed and approved.

- Electrical: Supply and install cable tray, power cable, low voltage switchboard, conduits and fittings, field disconnect switches, electrical heater tracing, instrument. All required tests must be completed and approved.

- Structural: Supply and install equipment, piping, and electrical supporting structures.

The new oxidizer system must seamlessly integrate with IKO's existing shingle production facility, therefore we've carefully planned the project to minimize disruption to their operations.