Roberts Onsite's Automation Controls & Engineering group designed and installed a comprehensive machine safeguarding solution for manufacturing equipment at an area university.

Our team completed an audit of more than 140 machines in 15 fabrication and production environments to get a full understanding of the safety remediations required.

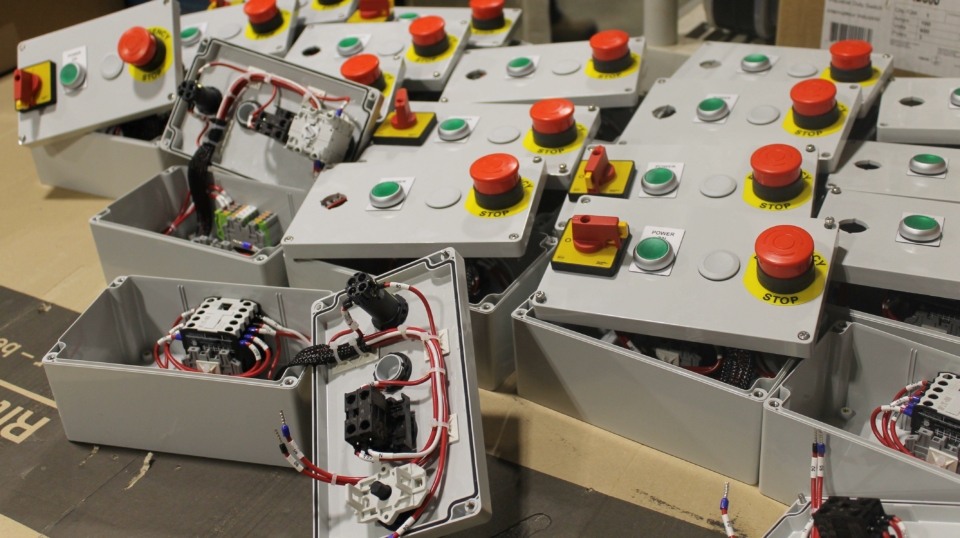

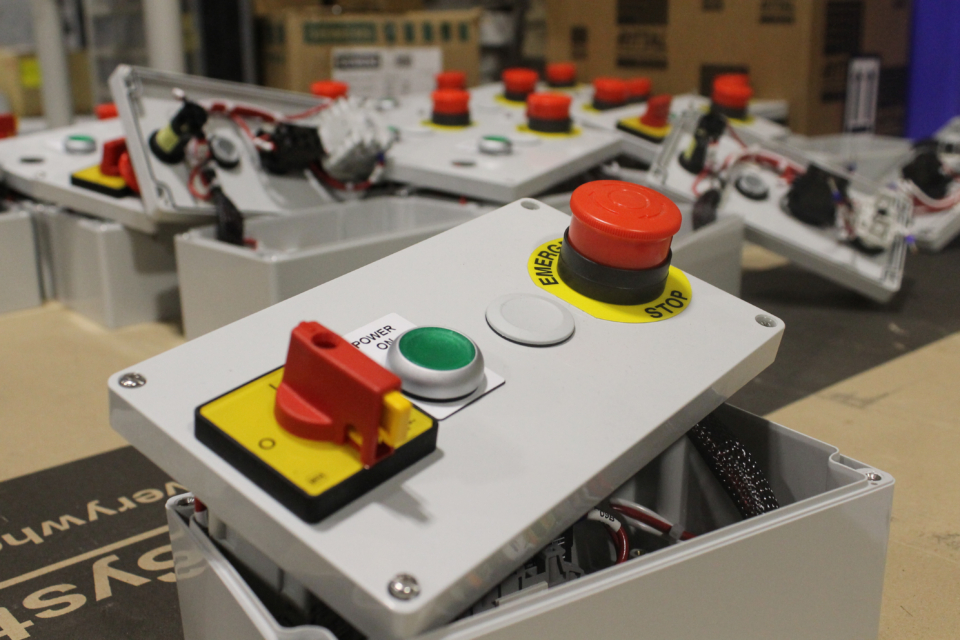

We designed a system that combined standardized controls in the form of a machine safety control box (MSCB), together with customizable point-of-operation guarding. To ensure our solution met the needs of the university, we developed prototype sample sets to show all stakeholders for their review, input, and approval. Once approval was received, our electricians manufactured the MSCBs in our QPS-certified panel shop.

The on-site installation was completed by our team of electricians and millwrights. A machine start-up report, which included Lockout/Tag Out, and Safe Operating Procedure documents, was completed and attached to each machine. Before leaving site we completed a post-installation audit and final inspection to validate the proper functioning of the safeguarding solution and that a high level of safety was achieved.